Liquid Levelling System (LLS)

Operating Principle and Application Areas

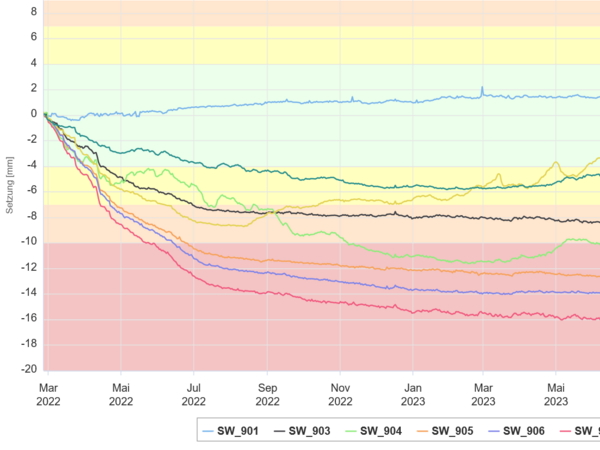

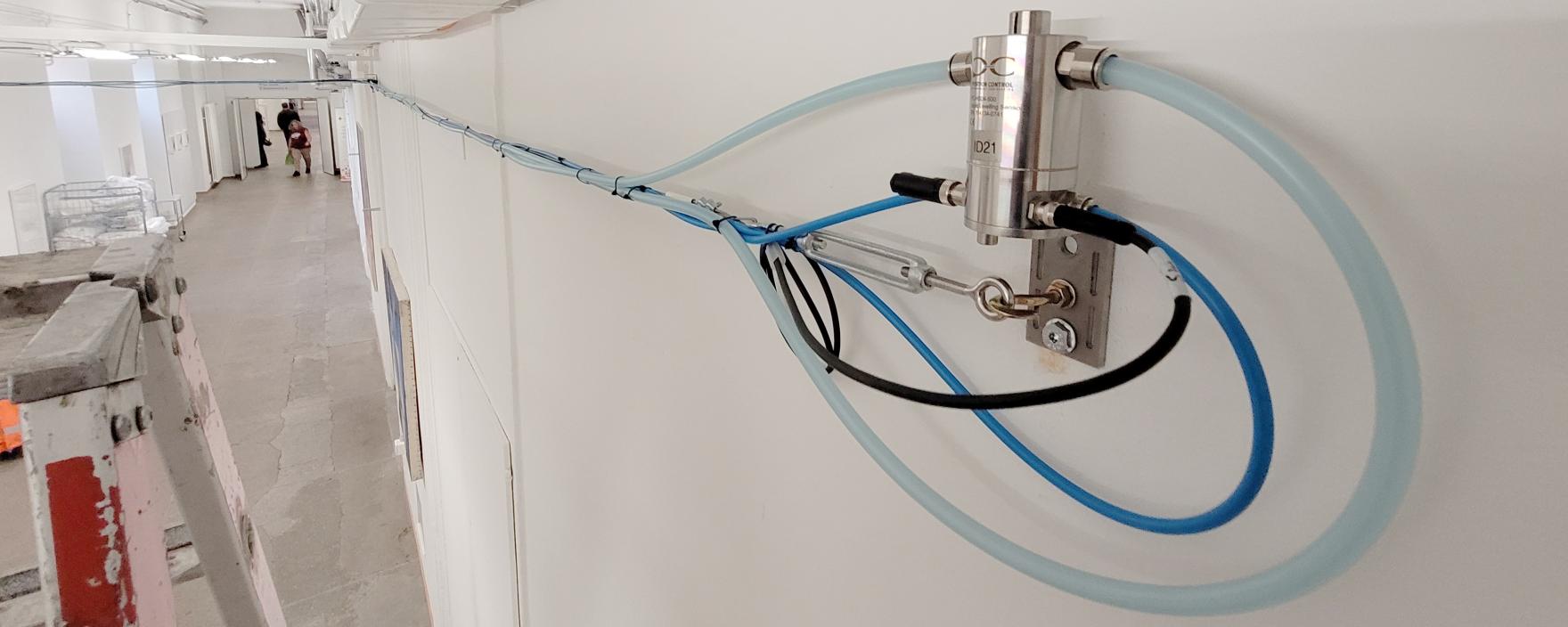

A liquid levelling system is primarily used in and around buildings to measure differential settlements of a structure. This system is the preferred choice when direct line of sight between measurement points is not possible. The method of hydrostatic height determination allows simultaneous observation of relative height movements between multiple points.

The operation of a liquid levelling system is based on the principle of communicating vessels, where the liquid levels in the measuring vessels connected by hoses form a horizontal plane when at rest. A change in the elevation of a vessel causes a corresponding change in the liquid level, which is measured by a highly sensitive pressure sensor and converted into a change in height.

Accuracy and error Influences

Hydrostatic liquid levelling systems are highly precise measurement instruments capable of achieving accuracies in the submillimeter range, which makes them particularly valuable for numerous applications.

The greatest influences on the accuracy of these systems are diverse and primarily include temperature variations, which can cause expansion or contraction of the hose, thereby potentially distorting the measurements. Air bubbles within the hose can also significantly affect measurement accuracy by disrupting the hydrostatic equilibrium. Additionally, dirt particles in the water or within the hose can interfere with precise measurements.

Furthermore, precise calibration and careful handling of the liquid levelling system are crucial to ensure maximum accuracy and reliability.